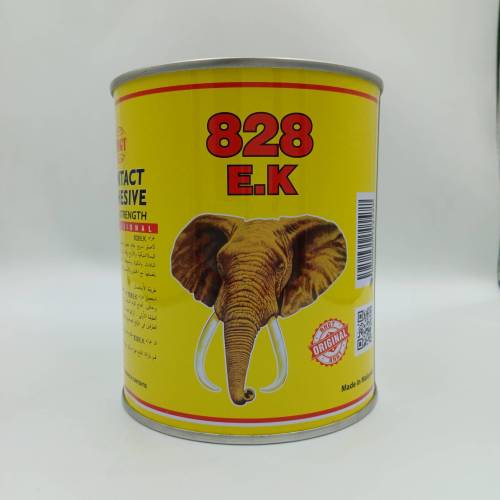

In industrial and construction environments, where strength and durability are essential, the need for a high-performance adhesive becomes critical. Elephant 828 has earned a strong reputation for consistently delivering reliable results under pressure, making it a go-to solution for heavy-duty applications. Engineered for demanding conditions, it combines flexibility, durability, and long-term bonding performance in one powerful formula.

Whether it’s for structural assembly or critical repairs, this adhesive ensures professionals can complete demanding jobs with efficiency and confidence. Its combination of industrial-grade performance and user-friendly application simplifies complex workflows while upholding quality standards.

Why Professionals Trust It in Critical Situations

When failure isn’t an option, this solution rises to the occasion. In both on-site installations and factory settings, it’s appreciated for its resistance to stress and environmental extremes. Professionals value how it performs across changing conditions—offering a firm hold without peeling, softening, or breaking down over time.

- Outperforms traditional adhesives in high-pressure, high-heat environments

- Maintains a secure hold despite movement or vibration

- Ideal for sectors like transportation, HVAC, and mechanical repair

- Requires no special equipment—making it easy to integrate

- Delivers consistent results, reinforcing its role as a trusted industrial adhesive

This adhesive has gained respect for its strong grip, rapid setting, and long-term performance. It’s especially useful in high-stress scenarios, from manufacturing to construction, where clean application and predictable output are essential for maintaining workflow integrity.

Unmatched Performance and Versatility

The real strength of this adhesive lies in its ability to work across multiple surfaces and materials, including rubber, metal, wood, composites, and plastic. It’s made to deliver high performance in unpredictable environments—outdoors or indoors, under heat or in humidity—without losing adhesion or compromising bond quality.

Its resistance to moisture, chemicals, and temperature changes makes it suitable for industries ranging from construction to automotive and infrastructure. The result is a flexible yet powerful bond that stands up to daily wear, heavy use, and extreme weather.

Practical Applications in Demanding Industries

Professionals count on this adhesive in a variety of settings, including:

- Machinery assembly and structural repairs

- High-stress molding and panel applications

- Projects requiring flexibility combined with enduring strength

- Installations exposed to vibration, heat, and pressure

These use cases show how its bonding performance supports projects in rigorous environments, reducing the need for constant maintenance or frequent replacement.

Features That Support Industrial Workflows

Each component of this adhesive is designed to solve real-world challenges. Its formula ensures:

- Strong adhesion between different materials

- Endurance in moist or chemically aggressive environments

- Stability in high and low temperatures

- Elasticity that absorbs stress and prevents cracking

These qualities allow it to serve not just as a glue, but as a strategic asset in industrial and commercial workspaces.

Efficient Use and Seamless Integration

Another reason for its widespread use is how easy it is to apply. Dispensing is clean and controlled, and there's ample time to position surfaces before curing begins. Preparation is minimal—clean and dry surfaces are typically all that’s needed. This saves time without sacrificing performance and keeps the job site cleaner and more organized.

Designed for Long-Term Value

What makes this adhesive cost-effective isn’t just its durability, but how much it reduces waste and repeat work. Its ability to bond multiple surfaces means fewer product types are needed in inventory. And with a longer life expectancy under stressful conditions, it minimizes the risk of breakdown or failure that would otherwise require rework or replacement.

Over time, its performance translates into tangible savings for contractors, builders, and engineers.

Final Thoughts

In high-stakes industries, choosing the right adhesive can make the difference between a short-term fix and long-term success. Elephant 828 stands apart for its strength, versatility, and resilience. With each application, it provides peace of mind—knowing the bond will hold strong, no matter the challenge. Professionals across sectors continue to rely on Elephant 828 for the demands of modern construction and manufacturing. Whether bonding metals, resisting vibration, or enduring temperature extremes, it proves to be an adhesive solution you can count on.

Add Comment