Introduction

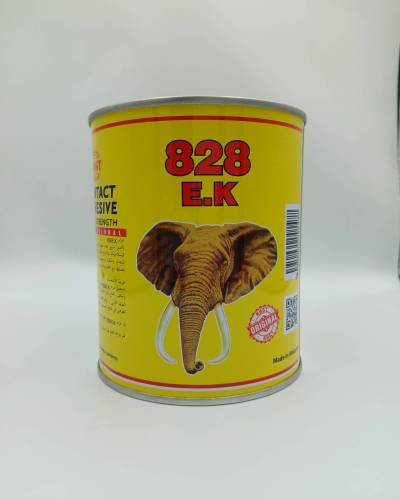

In construction, manufacturing, and product assembly, few things are more important than a reliable bond. Every project depends on materials staying firmly connected, even under stress, heat, or vibration. Professionals know that not all adhesives can deliver this kind of performance consistently. That’s why Elephant 828 has become a trusted solution—offering unmatched strength, efficiency, and dependability in demanding environments.

Built for industrial use yet versatile enough for smaller applications, this adhesive stands apart because it does exactly what every craftsman, engineer, and technician expects—create bonds that last. Whether you’re building, repairing, or reinforcing, this formula ensures that once joined, materials stay joined.

Engineered for Strength and Versatility

The defining quality of this adhesive lies in its powerful chemical formulation. Designed with advanced polymers, it creates a high-strength layer capable of holding together metals, plastics, woods, and composites. Its resistance to moisture, heat, and vibration makes it ideal for both indoor and outdoor applications. Unlike general-purpose glues that lose effectiveness over time, this compound remains stable even under pressure, maintaining integrity where others fail.

Key advantages include:

- Exceptional bond durability: Performs under stress, temperature swings, and mechanical load.

- Multi-surface compatibility: Works seamlessly across materials from wood to steel.

- Fast curing: Reduces downtime without compromising strength.

- Weather resistance: Withstands humidity, dust, and UV exposure.

Because it’s user-friendly, contractors and technicians appreciate how easy it is to apply. The controlled viscosity allows even spreading, while its quick-set nature saves valuable working hours—a major advantage in fast-paced industrial environments.

Applications That Deliver Real Results

From large-scale construction to precision engineering, this adhesive adapts to virtually any task. In metal fabrication, it’s used to assemble and seal structural parts without rivets or bolts. In the automotive and marine industries, it secures trims, gaskets, and composite components that must endure vibration and harsh conditions. Even in furniture manufacturing or home repairs, it provides professional-grade bonding without the need for specialized tools.

Common use cases:

- Structural bonding in construction and assembly lines.

- Panel and fixture adhesion in industrial installations.

- Equipment maintenance and repair for long-term reliability.

- DIY or home improvement projects that require heavy-duty adhesion.

Its ability to maintain strength over time means fewer repairs, fewer replacements, and greater overall cost efficiency—qualities every professional team values.

How to Get the Best Results

To maximize adhesive performance, preparation is key. Clean and dry both surfaces thoroughly before applying the compound. Remove any oil, dust, or loose debris that might interfere with adhesion. For non-porous materials like metal or glass, lightly roughen the surface to improve grip.

Apply a consistent, even layer using a brush, roller, or nozzle, depending on your setup. Press both surfaces together firmly and allow curing time according to the manufacturer’s recommendations. Good ventilation is essential during use, especially in enclosed areas. Store the product in a cool, dry place to preserve its shelf life and maintain quality.

Quick pro tips:

- Don’t over-apply—thin, even coats create stronger bonds.

- Avoid using in extremely high-temperature environments.

- Check cured joints after a few hours for proper setting.

Proper handling ensures every project benefits from the adhesive’s full strength and performance potential.

The Professional’s Choice

For contractors, fabricators, and maintenance experts, reliability defines success. Projects must not only look perfect but also perform under pressure for years. That’s why so many professionals trust high-performance adhesives engineered for real-world conditions. Elephant 828 stands at the forefront of this category—known for its consistent results, long-term durability, and adaptability across industries.

When every bond matters, using a product built for endurance makes all the difference. This adhesive doesn’t just connect materials; it connects precision with peace of mind.

Conclusion

Choosing the right adhesive is about more than just holding things together—it’s about ensuring safety, stability, and efficiency. This industrial-strength solution provides exactly that: superior adhesion, wide-ranging material compatibility, and proven durability. From large construction sites to everyday repair work, it delivers performance professionals can rely on. Strong, steady, and built to last, it remains one of the best choices for anyone serious about long-term results.

Add Comment